Category : Dyno Test & Tune

Back to Blog

Share This

Where Does the SC pulley go???

Well as many of you know we have had our new 07 Mini Cooper S for a few weeks now. In those few weeks many new items have been developed. Many mimicking parts we offer for the Supercharged cars. Even a €œSupercharger Pulley€ type of part for the R56 is in the works. If there was a way to let only our customers read this and not our competitors, we would, but hey, this info will help educate our future R56 customers and hopefully get them to buy our parts! Lets start with what kind of power the R56 makes. According to Mini USA, the new car is supposed to make 172 horsepower, with 177 pound-feet of torque, up 4hp, and 22ft-lbs. Like other dyno runs we have done in the past, we started with a Dynopack Dyno. On the scale of high and low reading dynos, its right in the middle, so results will not be skewed one way or the other. We spent a lot of time setting up the dyno so results would be more accurate and consistent. Start RPM had to be adjusted because the car built boost so quick, as well as other things. But once we were all set, it was time to do a run. For the fans we used 2 big fans and the hood closed. Both positioned about 2ft from the bumper. Lastly one of the parameters we messed with was the start RPM. Because this car build boost instantly, too high a number resulted in 14psi of boost just sitting there when the dyno launches. We ended up with 1300 RPM, where the car would build about 4psi of boost before the dyno let it go. This instant response is why small turbos can be a good thing. Hmmmm, something doesn€™t seem right here. We were making more power and more torque at the wheels than the engine was rated for. We checked to make sure the setting were correct, and they were. So why is the power so high?? We have our theories, but that is all to be discussed some other time. Sport mode did nothing but improve throttle response, the boost level, and boost consistency was the same. But boost consistency played a big part in consistent power. There seemed to be 2 different boost curves we would see. The most common was a peak of 15psi, dropping to 13psi, then back to 16psi, then dropping off to 12psi. A big roller coaster! Then about every third run, we would see a very low boost curve. Peaking at 11psi, dropping to about 9psi, then climbing to 14psi, then back down to 10psi. Because we were logging everything going on in the car, there was nothing we really saw that caused this. Even on the road we noticed these strange occurrences. So needless to say, during the testing, all the €œLow boost€ runs were removed and not accounted for.INTAKE SYSTEM TESTING BEGINS€¦€¦€¦.

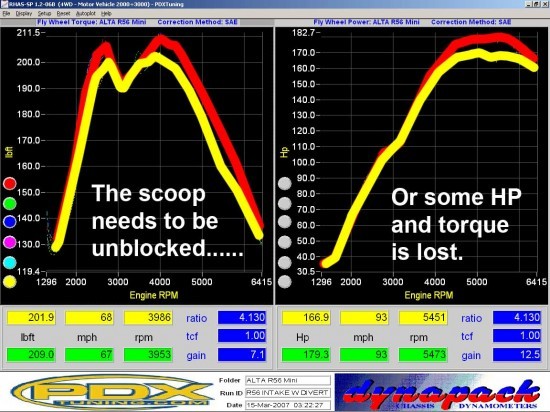

Our initial test of the intake system was done with the OEM hood scoop left in place. Our intake is designed to remove this, but we wanted to prove how this was a necessary mod. So we did 3 quick runs with the scoop on and 4 quick runs with the scoop off. Below are the runs, with the strange low boost runs removed. The dyno€™s runs are redrawn over with a wide brush to show the average of the 2 runs. With no scoop, the filter temps constantly climbed. In 3 quick (10 second interval) runs, the temps were at 150 degrees. With the scoop removed, an instant 30F drop occurred, and a constantly cooling temp change started. The next 3 quick runs showed a nice change in both temp and Wheel HP. The gain was somewhat expected, and the scoop needed to be removed to get the most from the intake system. Above graph shows averaged runs with and with the scoop being blocked.

So where is the €œcomplete€ cold air intake?? The feasibility for a cold air intake is never out of the question, but the cost is the issue here. We wanted to bring the best bang for the buck to the plate first, not scare people away. Since our intake did so well in its form you see here we will continue with developing it this way. Plus we have some things up our sleeves to make it even better.

On a side note, when dealing with MAF (Mass Air Flow) sensors, small changes to turbulence in the intake system, can make huge changes to how the car runs. Because we are familiar with this problem on other cars, great care was taken to eliminate any turbulence issues that might throw a CEL, or make the car run too lean or rich. We can say for a fact that our intake replicates the stock MAF curve nearly perfectly!

Above graph shows averaged runs with and with the scoop being blocked.

So where is the €œcomplete€ cold air intake?? The feasibility for a cold air intake is never out of the question, but the cost is the issue here. We wanted to bring the best bang for the buck to the plate first, not scare people away. Since our intake did so well in its form you see here we will continue with developing it this way. Plus we have some things up our sleeves to make it even better.

On a side note, when dealing with MAF (Mass Air Flow) sensors, small changes to turbulence in the intake system, can make huge changes to how the car runs. Because we are familiar with this problem on other cars, great care was taken to eliminate any turbulence issues that might throw a CEL, or make the car run too lean or rich. We can say for a fact that our intake replicates the stock MAF curve nearly perfectly!

Above graph shows averaged runs with and with the scoop opened up and intake installed!

Above graph shows averaged runs with and with the scoop opened up and intake installed!

Next up, the Cat-back exhaust€¦.

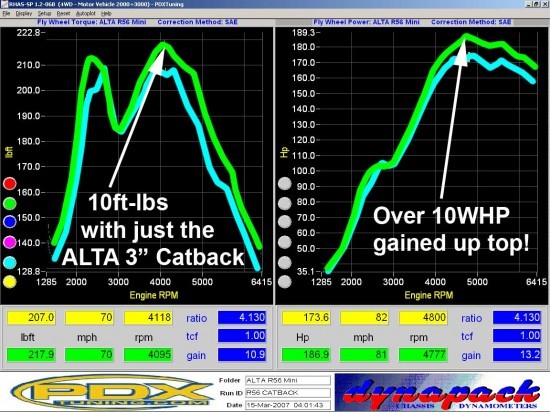

For all these tests we started with the car being bone stock. So the OEM intake went back on. The catback exhaust is comprised of just that, an exhaust that starts after the cat(s). Yes there are 2 cats on these cars! This part is what we feel is going to be the most popular part to install, because of the sound and HP gains, and legality of it. The legality comes from the fact that it isn€™t a part the CARB cares about, and it doesn€™t mess with EPA issues. The only thing that the catback will have issues with is noise, and we will be far under any states maximum decibel level. The ALTA 3€ Catback is comprised of 3€OD,18g 304SS tubing, with V-band connections where needed. V- band connections provide a leak free, gasket less connection, that allows for rotation of the 2 joints. The look of the muffler section we wanted to keep similar to stock, but more beefy. With the larger round dual wall, twin tips, and polished can, I think we make it as perfect as we could. The sound of the catback is very mellow and not much louder than the OEM system. The OEM Exhaust is made from 2.166 or 55mm OD tubing, so needless to say, its small for a turbo car. So how do we connect the catback to the small OEM system? With a small adapter! Behind the last cat, you simply cut the exhaust, and slip our system on! Simple job anyone with a hack saw can do. With all these features at a reasonable price, it will be hard to beat what we are offering. On to the test. Like our other parts, we did many runs to prove the gains were not a fluke. After our 7 or so runs we saw a great average gain of 10WHP and 10ft-lbs of torque above 4500 RPM. The only thing we plan on changing is the sound. In catback form, it is almost too quiet. So, a slight muffler change for a slightly louder sound and we are done. Because of how quite this is, look for 2 different versions one louder than the other. Above graph shows averaged runs with the 3" ALTA catback installed.

Above graph shows averaged runs with the 3" ALTA catback installed.

TURBO BACK TIME!

Next up was the turbo back exhaust. The turbo back exhaust consists of the same basic parts as in the cat back, add a 3€ mid section with CARB legal cat, and a downpipe with another CARB legal cat. The complete turbo back system is 3€ everywhere, but the first 8€ are 2.5€ tubing to make the turbo connection and gain clearance around the header. One of the most important features is that the OEM heat shields fit over the downpipe. This we feel is very important as the turbo sits so close to the hood. Onto the dyno test. Like the catback by itself adding the downpipe and midpipe netted very good gains. We gained more than 20WHP and 20ft-lbs which is awesome considering the car still runs the same boost levels during these runs. Besides the HP we gained during the runs, one thing we noticed was while the car was in its holding pattern on the dyno, it was getting 7psi of boost now, not the 4-5. This is also seen on the graphs by the huge 40ft-lbs gained at 2000 rpm! So another important thing to take note of! This would definitely be noticeable on the road at low rpm. Sure enough, on the freeway cruising around, we get nearly instant boost response. We are setting the standard from which others will be judged from. Yes another company has an R56 exhaust out, but its 2.5€ and they never did a before HP run. So they claim it makes 27HP because they made 202 at the engine, and since the stock car is supposed to make 175, it must make 27HP. Not very good proof IMHO. Above graph shows averaged runs with the 3" ALTA Turboback installed.

Above graph shows averaged runs with the 3" ALTA Turboback installed.

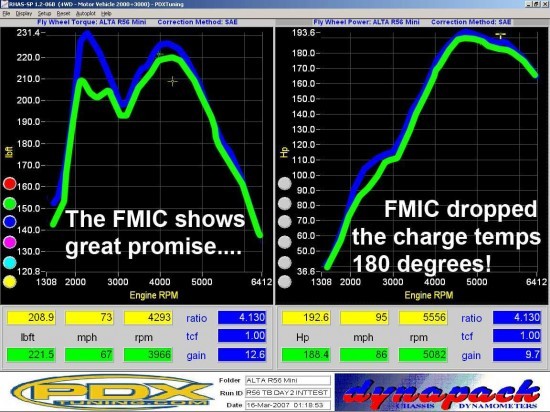

FMIC TIME!!

Finally Mini put a front mounted intercooler on this car! Compared to the R53 intercooler, the size of the R56 IC is bigger and much better place. But once again Mini could have done a little better. First off half the IC sits under the bumper. This is not good! So one of the first non-obvious parts we made and tested was an IC diverter. A simple but optimally sized plate that diverts the air down to the IC. We did all of our tests above with out this to make the results more €œreal world€. But our initial tests showed a pretty noticeable change in air temp, and IC temp recovery. First off, the first 4 runs, the post IC temps would go to about 150-151 at the end of the run. Between runs we had about a 40 seconds of recovery, which post IC temps would drop to 129-130. With the diverter installed, we saw a solid 6-7degrees of drop! This is only with a single fan in the front of the car, definitely not a good representation of air flow you might see on the road. So the potential for this to be a good inexpensive mod once on the road is proven with minimal air flow. Now to our first FMIC prototype. Using the €œno IC is too big€ theory, which works 90% of the time, we set out to build 2 different styles of IC€™s, but first some basic calculations of the OEM IC and our potential ALTA IC€™s. Using how the OEM IC is constructed, tube and fin, and comparing it to our potential bar and plate cores, we found we could make a core that fits in the OEM position and make it larger with more surface area, and a less restrictive core. We found we could make the Surface area bigger, and the ambient charge side bigger. Another simple calculation we made was the volume of the charge side entry. This would give us a way to compare how dense the OEM core is and compare it to ours which in turn gives us an idea on how restrictive the core might be. The first potential ALTA IC would be freer flowing as the charge side density was less given the overall increase in size, and it would cool the air better. So this all sounds good, except it wasn€™t enough. For a small increase in these benefits, we would still be battling with ambient air flow issues. So IC design number 2 was calculating out to be better, and look far cooler. Like you would expect it to!A few stats of the Intercoolers

ALTA proto vs. OEM

Cubic Inches 215% bigger

Charge Square Inches (charge tube only) 155% bigger

Fin density per square inch 20% less

Charge side square inch minus fin density 158% more

What does all this mean? Bigger core, more cooling potential, bigger freer flowing core, less pressure drop. So we know what we need to build on paper, on to the test. We have a plethora of different cores laying around the shop so creating the prototype was easy. Some sheet metal, and a couple of modded cores, and we have our proto. First off the proto fits the car perfect and if you made it to AMVIV you saw how it filled the bumper! First few pulls showed great gains down low. The peak HP was about the same which has a lot to do with the boost the ECU runs at 5000RPM. Like previous runs sometimes the ECU would just not run the higher boost. But when it did the higher boost runs, we saw an increase in boost and power at low RPM. But because we were getting a little more boost than the ECU liked, it would close the Throttle body close to redline. Which I think that we could have seen more power from 6000 RPM up, had we been able to tune the ECU to run more boost. But very good gains at low RPM were had which is great sign of things to come! Driving impressions. There is ZERO change in response. Even thought the volume changed, the turbo spools so quick there is not a single difference in feel, except more power!

An important thing to take note of is that the charge temps were far cooler. Before we were seeing about 150-155 at the end of the run, and 130 before each run. With the IC installed we never saw more than 110 degrees at the end of the run and 105 before each run. This is a huge improvement! We calculated STOCK IC efficiency at 63%, and ALTA IC efficiency at 85%, which is great! The core we used we have tested many times to show it is slightly restrictive, but cools very well. With the increase in boost we saw, and a slight change to get the pressure drop back to 1psi range (stock is no where near 1psi) I think there is a huge potential for this part. Especially when we start tuning the ECU to run more boost (higher charge temps), the ALTA FMIC will shine!

The final prototype core will be tested in the upcoming weeks, so keep your eyes peeled for that!

Driving impressions. There is ZERO change in response. Even thought the volume changed, the turbo spools so quick there is not a single difference in feel, except more power!

An important thing to take note of is that the charge temps were far cooler. Before we were seeing about 150-155 at the end of the run, and 130 before each run. With the IC installed we never saw more than 110 degrees at the end of the run and 105 before each run. This is a huge improvement! We calculated STOCK IC efficiency at 63%, and ALTA IC efficiency at 85%, which is great! The core we used we have tested many times to show it is slightly restrictive, but cools very well. With the increase in boost we saw, and a slight change to get the pressure drop back to 1psi range (stock is no where near 1psi) I think there is a huge potential for this part. Especially when we start tuning the ECU to run more boost (higher charge temps), the ALTA FMIC will shine!

The final prototype core will be tested in the upcoming weeks, so keep your eyes peeled for that!

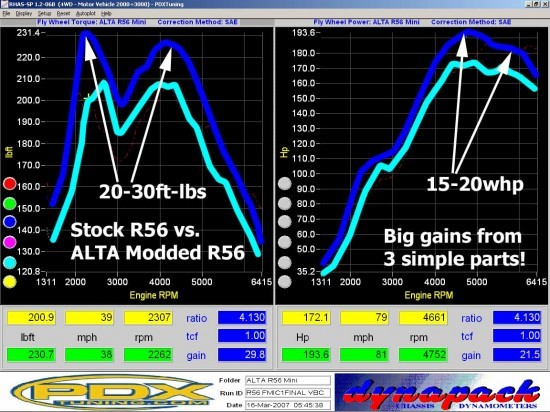

Above graph shows averaged runs with the 3" ALTA turboback, intake, and FMIC installed.

Above graph shows averaged runs with the 3" ALTA turboback, intake, and FMIC installed.

BOOST CONTROLER

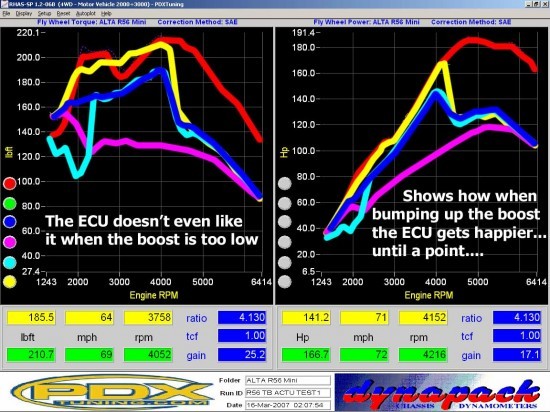

The first obvious part we thought of was some type of boost controller. Our first boost controller worked very well at controlling boost. But the ECU sure didn€™t like it. The ECU does 3 things to control boost. The ECU has an air control solenoid that varies its duty cycle to allow more or less vacuum (yes vacuum) to close or open the wastegate actuator to control boost pressure. If the engine is running more or less boost than programmed, the ECU first uses the solenoid to control the actuator, if that doesn€™t work, then it blows the BOV off. Finally if that doesn€™t work, the ECU closes the TB. When setting up and testing our 2 different boost controllers, we had a hell of time getting it just right. So we had to come up with a solution to the BOV blowing off, and keep the ECU happy. After some minor tweaks to the ALTA Blow Off Valve, we solved that problem. Now onto adjusting boost. Below is and example of some of the runs doing just that, and comparing it to a couple runs with the OEM boost controller. The really low power runs show the boost controller set below the stock boost setting and shows the ECU closing the TB and making the BOV blow off. Above is our first runs with our boost controller installed. This shows that not enought boost and the ECU freaks out an dcloses the throttle body, and makes the BOV blow off.

Above is our first runs with our boost controller installed. This shows that not enought boost and the ECU freaks out an dcloses the throttle body, and makes the BOV blow off.

Above is our best run with our boost controller installed. This shows that great power can be had, but a bit too much boost at upper RPMS made the ECU close the throttle body and loose power.

After the above runs we backed off boost a little to keep the ECU happy. We lost some of the peak power, and low end power, but got rid of the huge loss in torque. Over all the highest HP was had with the boost controller running on the ragged edge of what the ECU liked. If we can hold this, I think there is more than 30ft-lbs to be gained at lower RPM and easily 20WHP gained at low RPM. Our 2 different boost controllers will be available soon, but until there is a flash to get rid of the boost limits, it is kind of a pain to setup. This part will go hand and hand with an ECU flash when they are available.

A question that arises is, can this kind of boost control be flashed into the ECU? Who knows, because the wastegate actuator is vacuum controlled, I believe that some boost can be added, but not tons as the actuator may have a hard timing staying closed under boost, and when the turbo is first spooling up. But the 2 different ALTA boost controllers with an ECU flash will definitely work and work very well.

Above is our best run with our boost controller installed. This shows that great power can be had, but a bit too much boost at upper RPMS made the ECU close the throttle body and loose power.

After the above runs we backed off boost a little to keep the ECU happy. We lost some of the peak power, and low end power, but got rid of the huge loss in torque. Over all the highest HP was had with the boost controller running on the ragged edge of what the ECU liked. If we can hold this, I think there is more than 30ft-lbs to be gained at lower RPM and easily 20WHP gained at low RPM. Our 2 different boost controllers will be available soon, but until there is a flash to get rid of the boost limits, it is kind of a pain to setup. This part will go hand and hand with an ECU flash when they are available.

A question that arises is, can this kind of boost control be flashed into the ECU? Who knows, because the wastegate actuator is vacuum controlled, I believe that some boost can be added, but not tons as the actuator may have a hard timing staying closed under boost, and when the turbo is first spooling up. But the 2 different ALTA boost controllers with an ECU flash will definitely work and work very well.