Category : Dyno Test & Tune

Back to Blog

Share This

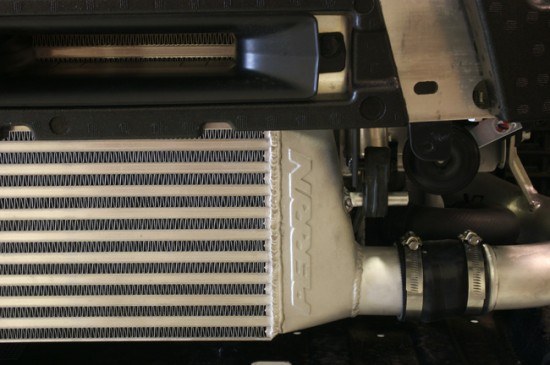

This is just our prototype core we had built. This was built using a few basic things like make it as big as possible while still fitting easily. One interesting thing we found was the core wasn't centered to start with. It actually is off center by about .75" or so. Not very noticeable unless you start measuring things. So besides fixing that, we went as reasonably deep as we could, and as tall as the ambient air would still flow through it. It looks like Mitsubishi (using the same size core) got smart about making the bumper match the IC size. THe downfall is it eliminates a few inches on each side for us to make the core wider!

This is just our prototype core we had built. This was built using a few basic things like make it as big as possible while still fitting easily. One interesting thing we found was the core wasn't centered to start with. It actually is off center by about .75" or so. Not very noticeable unless you start measuring things. So besides fixing that, we went as reasonably deep as we could, and as tall as the ambient air would still flow through it. It looks like Mitsubishi (using the same size core) got smart about making the bumper match the IC size. THe downfall is it eliminates a few inches on each side for us to make the core wider!

You can see by the pics that there isn't lots of room to go too much wider. But we push the limits of the core and bumper to ensure all the air goes through the core. This leaves virtually no welds showing from the outside of the car. Other than that we use the OEM type of hanger system to secure the core. This teamed with the lower brackets makes the core rock solid.

You can see by the pics that there isn't lots of room to go too much wider. But we push the limits of the core and bumper to ensure all the air goes through the core. This leaves virtually no welds showing from the outside of the car. Other than that we use the OEM type of hanger system to secure the core. This teamed with the lower brackets makes the core rock solid.

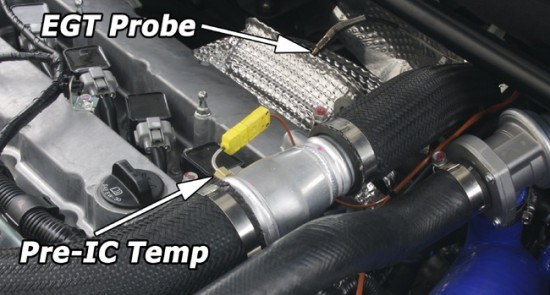

Test Time

Onto the test! For this test we had just finished tuning Stage 1 with the Unichip and bolted on our Turboback exhaust. We left the bumper off for the test in order to be able to swap the cores quickly. The bumper beam was left on also. This may put both cores at a slight disadvantage with loosing some of the plastic diverters on the bumper, but still it makes them both equal. Another thing is our tanks we were using some prototype tanks we built not production cast aluminum tanks. Then one more thing to keep in mind (important when comparing other IC tests out there) our car is tuned! This isn't the stock ECU tuning! Or stock boost! Like some of our other tests we have show on the net, we are using the Innovate logging hardware to log temps and other important data. Our (3) temp probes are mounted as follows. One in the aluminum boost tube right after the turbo, one in the lower charge pipe after the intercooler, and the final one is right in front of the IC for ambient temps. Along with we do have boost, EGT and a few other things hooked up. The only other thing we would be measuring is EGT's. Normally the IC's don't effect this too much, but we noticed a huge difference in some instances.

Like some of our other tests we have show on the net, we are using the Innovate logging hardware to log temps and other important data. Our (3) temp probes are mounted as follows. One in the aluminum boost tube right after the turbo, one in the lower charge pipe after the intercooler, and the final one is right in front of the IC for ambient temps. Along with we do have boost, EGT and a few other things hooked up. The only other thing we would be measuring is EGT's. Normally the IC's don't effect this too much, but we noticed a huge difference in some instances.

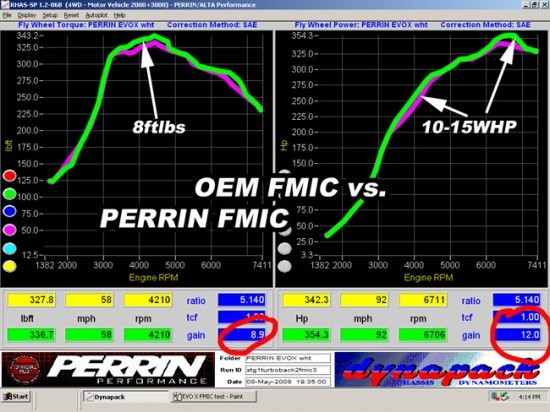

HARD DATA

After a few runs, the IC outlet temps seemed to keep getting worse. We did about 4 runs with about 30 seconds between them. The peak IC outlets temps started at 140 and by the last run, 149 degrees! This is what we seen on small IC's mounted in crappy places (STI), not on an EVO! So why is the question?? The EGT's caught my eyes as they seemed a bit high. The first run peaked at 1678F, hot for sure, and something too keep an eye on. By the final run 1701F was the highest. These are pretty toasty! So why?? The Pre-IC temps were astronomically high! Normally we see 250-300 on a turbo that is really working or being pushed beyond its normal efficiency range. But we were seeing 400F! You could bake cookies at that temp!! This was only on the first run! The second run was 418F which it stabilized out from there. Still this is nuts! So again WHY?? We will answer that later. So with some scary data behind us we thought, our IC must be able to do much better! It does and it deals with that extreme Pre-IC temps pretty well. The Pre-IC temps were still hot but about 20F cooler. First runs peaked at 380F, and the last run peaked at 400F. Well that is a good start. This drop in temp could be from the IC being less restrictive than the OEM core. We saw about .9psi vs 1.5psi drop. So the turbo has to work less to make the same boost, more efficient! Now the data that really matters. The Post-IC temps were much more inline, but still about 20F higher than we normally see. The first run showed a peak of 114F and the last run hit 120F. This was huge improvement. With a good tuning tool this could be worth a little extra timing and more power! Or, if nothing else a safer setup. EGT's also improved peaking from 1616F in the first run and 1636F. So overall the PERRIN FMIC ran more than 30F cooler on the IC oulet temps, and almost 80F cooler! All that means a happier safer engine.

Worst case scenario runs are shown below and temps taken at 7300RPM and the temps for the day were 67-71 degress.

So with some scary data behind us we thought, our IC must be able to do much better! It does and it deals with that extreme Pre-IC temps pretty well. The Pre-IC temps were still hot but about 20F cooler. First runs peaked at 380F, and the last run peaked at 400F. Well that is a good start. This drop in temp could be from the IC being less restrictive than the OEM core. We saw about .9psi vs 1.5psi drop. So the turbo has to work less to make the same boost, more efficient! Now the data that really matters. The Post-IC temps were much more inline, but still about 20F higher than we normally see. The first run showed a peak of 114F and the last run hit 120F. This was huge improvement. With a good tuning tool this could be worth a little extra timing and more power! Or, if nothing else a safer setup. EGT's also improved peaking from 1616F in the first run and 1636F. So overall the PERRIN FMIC ran more than 30F cooler on the IC oulet temps, and almost 80F cooler! All that means a happier safer engine.

Worst case scenario runs are shown below and temps taken at 7300RPM and the temps for the day were 67-71 degress.

Stock FMIC Tuned Stage 2 PERRIN FMIC Tuned Stage 2

3000RPM Inlet 245F/ Outlet 104F Inlet 238F/ Outlet 101F \ 7300RPM Inlet 412F/ Outlet 144F Inlet 398F/ Outlet 120F IC Efficiency 80%-78% at redline 82%-85% at redline. PEAK EGT's 1678-1701F 1616-1636F The lower RPM IC efficiency numbers are a little scewed as the temps just started to climb at this RPM. Which one made the most power? Again to be clear, this started as a stage 1 car with just FMIC's swaped from one set of runs to the next. Of course our core made more power. Now it wasn't tons but there are a few reasons for that. The super high turbo outlet temps, turbo is pushed to the max as far as flow, and we didn't turn the boost up from where it was or do any ECU tuning to really show the benefits. What was most important was consistency! The car would loose HP every run, and by the 5th run it was down 15WHP. With the PERRIN FMIC installed it only lost about 5WHP and it leveled off.

THIS ALL SOUNDS GREAT, WHEN CAN I GET MY PERRIN EVO X FMIC!

So where is our core?? Well we learned very quickly that sheetmetal tanks is huge labor sucker-upper, and cast endtanks work and look much better. So the downfall is this adds a bit of time (and cost) to get our FMIC out, but it will pay off to those who wait. Some may wonder what is involved with making endtanks? There are many steps, but I bet none of you expected to see wood involved in one of the steps! Step one is make a prototype set to use, and another to build a pattern from. We used a couple of our other cast tanks as a starting point, then started to cut an weld until the tanks were done. From there the part goes to the pattern maker who will create our part from one of many different materials, and most commonly use is wood! I know something you might find in your Benz on the dash! Maple and other dense woods are used to create both the inside cavity and the outside of the part. With a pattern finished, sand can be poured around the pattern, pattern can then be removed. The 2 halves are stuck together in a box, and molten aluminum is poored in. After cooling, out comes our end tanks! Basic prototypes of tanks with notes for the pattern maker

Basic prototypes of tanks with notes for the pattern maker

After some back and forth, and test fitting, pattern for the casting process are created

This makes it sound like its a long ways away, but actually our FMIC i just around the corner. This info may sound new to those reading it, but actually we have been sitting on this waiting to release it closer to when we can start shipping the FMIC's. In roughly 3 weeks parts will start showing up in customers hands!

After some back and forth, and test fitting, pattern for the casting process are created

This makes it sound like its a long ways away, but actually our FMIC i just around the corner. This info may sound new to those reading it, but actually we have been sitting on this waiting to release it closer to when we can start shipping the FMIC's. In roughly 3 weeks parts will start showing up in customers hands!