Category : Dyno Test & Tune

Back to Blog

Share This

We here at ALTA have done lots and lots of proving of parts over the years. 99% of the time parts do exactly what we want, or they do almost what we want and we modify them to make them work better. Nearly every part we have we have dyno graph for it to back it up. The R56 crank pulley is no exception. Just like our other parts, we have a very good back to back run to show how it works..... or doesn't work......

Our concerns with a crank pulley are that removing the harmonic dampener might cause damage (very rare cases on new engines, but still something to prove) and the fact that some engines produce more engine noise causing the ECU to pull timing. The second concern is easily seen on the dyno with rapid changes to torque. With both of those things said, the ALTA prototype R56 pulley has shown neither to be a concern.

There are calculations for how much HP a lighter crank pulley or flywheel will make based off the diameter, and overall weight removed by the part. With that said on every engine we have seen, we see about 5WHP gained from a lighter crank pulley. But this was the first time we had done a test on our own dyno.

Before we get to the results, its important to mention the difference in weight and construction. The OEM pulley is contrusted of 3 pieces. One is the inner steel par that contains the mounting flange for the crank. This piece is a not so precise stamped piece of steel. The outer part is a machined piece of steel also. The third part of the OEM crank pulley is a rubber band that is molded between the 2 pieces. This is the harmonic dampener part of the crank pulley. It even has the frequency at which its designed to dampen at, written on the band! This is a long standing argument amungst enthusiests about the harmonic damper actually being necessary. Our opinion is time will tell. The R56 crank pulley is ligher than the stock part by about 5 lbs or so.

Like other tests, we ran our 08 R56 at least 5 runs, to show consistency, then as quick as possible swapped the pulley and did 5 more runs. All with the same times between runs and all that other stuff to keep it as consistent as possible. In order to make this as quick as possible we pulled out the fender liner ahead of time and prepared with the tools we needed!

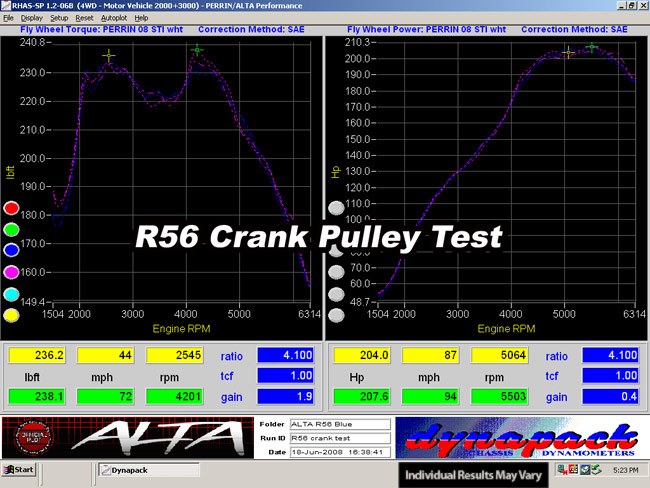

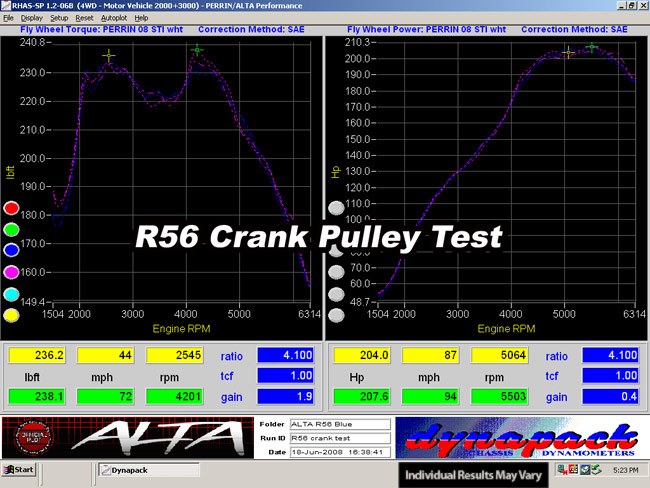

It's a little hard to tell by the graphs, but we eliminated the first and last runs and picked the middle runs to show off the power changes. As you see (or maybe don't see) the power changes are not really there.

Yup, that is right, it didn't do anything! Well if the calculations show it will make HP to the wheels why didn't it on our dyno? This could have to do with the fixed amount of time the dyno runs. Meaning on a roller dyno with no load cell, the lighter pulley would allow the engine to accelerate the drums faster, and it would calculate more HP to the wheels. This is just like when you change the wheels on your car (lighter ones of course), it gets faster and makes more HP to the wheels on roller types of dynos.

We know for a fact the crank pulley will increase throttle response which isn't a measurable thing on the dyno, and definitely something that can be felt by the driver. So while this part didn't make power, we are going to do further testing to ensure the engine and ECU stay happy with the pulley installed. In the next few months you will see our pulley either go up for sale, or an announcement that the part isn't going to be built. But with the time we have on it right now, I can bet you will see it for sale, not in the crapper!

It's a little hard to tell by the graphs, but we eliminated the first and last runs and picked the middle runs to show off the power changes. As you see (or maybe don't see) the power changes are not really there.

Yup, that is right, it didn't do anything! Well if the calculations show it will make HP to the wheels why didn't it on our dyno? This could have to do with the fixed amount of time the dyno runs. Meaning on a roller dyno with no load cell, the lighter pulley would allow the engine to accelerate the drums faster, and it would calculate more HP to the wheels. This is just like when you change the wheels on your car (lighter ones of course), it gets faster and makes more HP to the wheels on roller types of dynos.

We know for a fact the crank pulley will increase throttle response which isn't a measurable thing on the dyno, and definitely something that can be felt by the driver. So while this part didn't make power, we are going to do further testing to ensure the engine and ECU stay happy with the pulley installed. In the next few months you will see our pulley either go up for sale, or an announcement that the part isn't going to be built. But with the time we have on it right now, I can bet you will see it for sale, not in the crapper!

It's a little hard to tell by the graphs, but we eliminated the first and last runs and picked the middle runs to show off the power changes. As you see (or maybe don't see) the power changes are not really there.

Yup, that is right, it didn't do anything! Well if the calculations show it will make HP to the wheels why didn't it on our dyno? This could have to do with the fixed amount of time the dyno runs. Meaning on a roller dyno with no load cell, the lighter pulley would allow the engine to accelerate the drums faster, and it would calculate more HP to the wheels. This is just like when you change the wheels on your car (lighter ones of course), it gets faster and makes more HP to the wheels on roller types of dynos.

We know for a fact the crank pulley will increase throttle response which isn't a measurable thing on the dyno, and definitely something that can be felt by the driver. So while this part didn't make power, we are going to do further testing to ensure the engine and ECU stay happy with the pulley installed. In the next few months you will see our pulley either go up for sale, or an announcement that the part isn't going to be built. But with the time we have on it right now, I can bet you will see it for sale, not in the crapper!

It's a little hard to tell by the graphs, but we eliminated the first and last runs and picked the middle runs to show off the power changes. As you see (or maybe don't see) the power changes are not really there.

Yup, that is right, it didn't do anything! Well if the calculations show it will make HP to the wheels why didn't it on our dyno? This could have to do with the fixed amount of time the dyno runs. Meaning on a roller dyno with no load cell, the lighter pulley would allow the engine to accelerate the drums faster, and it would calculate more HP to the wheels. This is just like when you change the wheels on your car (lighter ones of course), it gets faster and makes more HP to the wheels on roller types of dynos.

We know for a fact the crank pulley will increase throttle response which isn't a measurable thing on the dyno, and definitely something that can be felt by the driver. So while this part didn't make power, we are going to do further testing to ensure the engine and ECU stay happy with the pulley installed. In the next few months you will see our pulley either go up for sale, or an announcement that the part isn't going to be built. But with the time we have on it right now, I can bet you will see it for sale, not in the crapper!