Share This

We can make this really simple. If you live on the east coast and/or own a 2008+Impreza/WRX/STI/Legacy and have more than 40,000 miles on your car, you need this part.

OEM Bushings Will Fail...

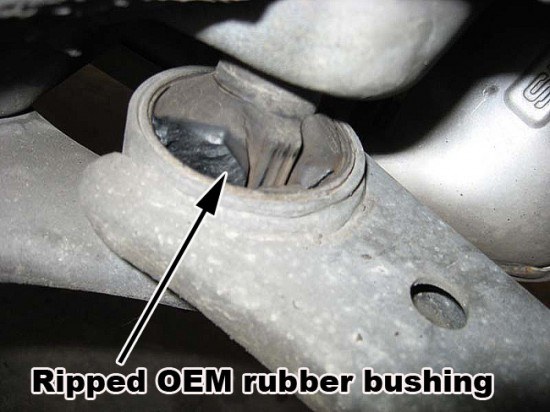

Ok being serious now, there are many reasons to want this part. They fail, they are super soft, negatively effect handling under braking and acceleration, and can add to wondering of your car from ruts in the road. Secondary reason to want this part is the added caster and removal of anti-dive/lift geometry to the front suspension, which helps with weight transfer under acceleration and braking. The most common reason to buy them is they fail. As you can see the picture below from a Legacy GT (Shares the same control arm as the 08-14 WRX and 08-10 STI) where the bushing ripped at 34,000 miles. This is more common to happen at 60K+ but still its not good. When the bushing rips, the control arm becomes loose vertically in the car, which then leads to a loose feeling in the front end, shakes in the steering wheel, and clunks as you go over bumps. In extreme situations (like hard driving or track day) the arm will slightly dislodge its self upward causing a constant misalignment of the front end. This is really bad!

The cars that don't' need this for durability reasons are 2011+ STI and 2015+ WRX/STI. These cars come standard with a spherical bushing encapsulated in rubber (shown below). Since they are constructed much better, they don't have that constant wearing and tearing happening at the rubber portion of the bushing. These cars still benefit from removing a flexible rubber bushing as well as the anti-dive/lift reduction feature.

Why Is This Called PSRS?

Something that annoys me is that we see people call these the PERRIN ALK or Anti-Lift-Kit. This is frustrating for few reasons, ALK is a term that another company came up with to describe what they felt was the main feature of their version of this part. Secondly, calling them an ALK or Anti-Lift kit, causes tons of confusion with customers as they think this parts reduces the amount of lift under acceleration they have. This is why we call our version of the LCA (lower control arm) rear bushing replacement as a PSRS (Positive Steering Response System). We feel that the change to the steering and feedback you get from the car far out weighs the features of the change to the Anti-Lift geometry. While both do good things is the other features that are more important.

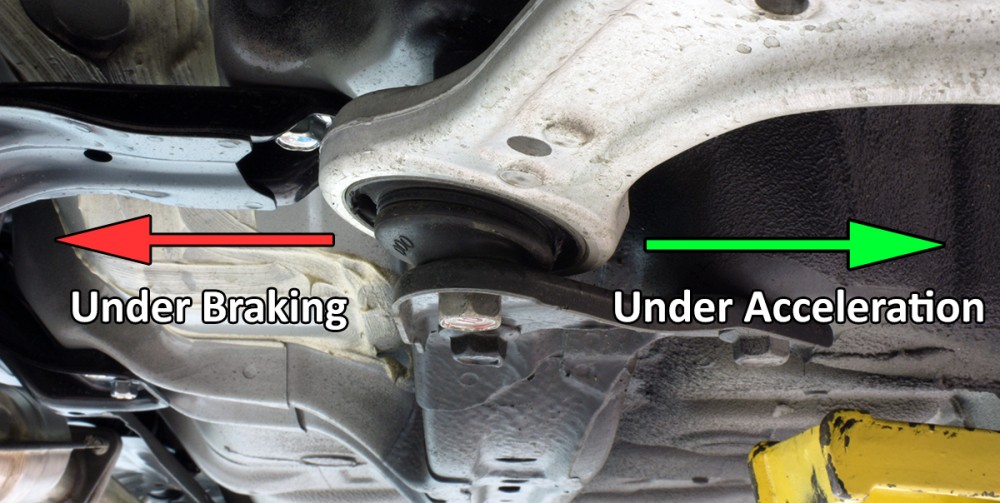

The biggest benefit of the PERRIN PSRS (for all cars) is the removal of the squishy rubber bushing on the car. All of our kits replace the front lower control arm, rear bushing, with a bearing or a super hard polyurethane bushing to remove nearly all deflection under extreme conditions. Using the above picture, you can see how under braking, that the control arm will want to deflect toward the inside of the car, and then under acceleration, the deflection happens the other way toward the outside of the car. When the control arm is deflected either direction, the alignment of the front suspension changes. As an example, your car is setup with zero degrees of toe in the front, and under braking you will get toe in, and under acceleration, you will get toe out. This can cause the car to have bump steer, effects how the car handles and can change the predictability of the car. Removing this unwanted deflection will greatly improve how the car handles under extreme conditions and create a more positive feel between you and the road. Customers love how the car feels like it wants to go where you point it, versus wondering around or wiggling under braking.

This leads us to the next thing customers really notice, which is how your car will not want to follow ruts in the road. With a stock car with stock wheels and tires, you won't notice this too much. The moment you put on stiffer suspension, and or wider wheels and tires, you will find that your car will want to wonder in the road between the ruts. This happens for a few reasons, but one of which is the front lower control arm bushings deflecting. Installing our PSRS significantly reduces this from happening and makes the car track much straighter on freeways and other roads that get rutted from heavy traffic.

Castor

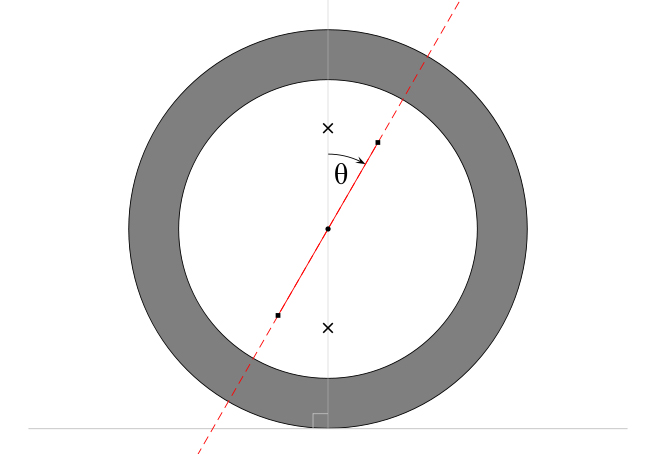

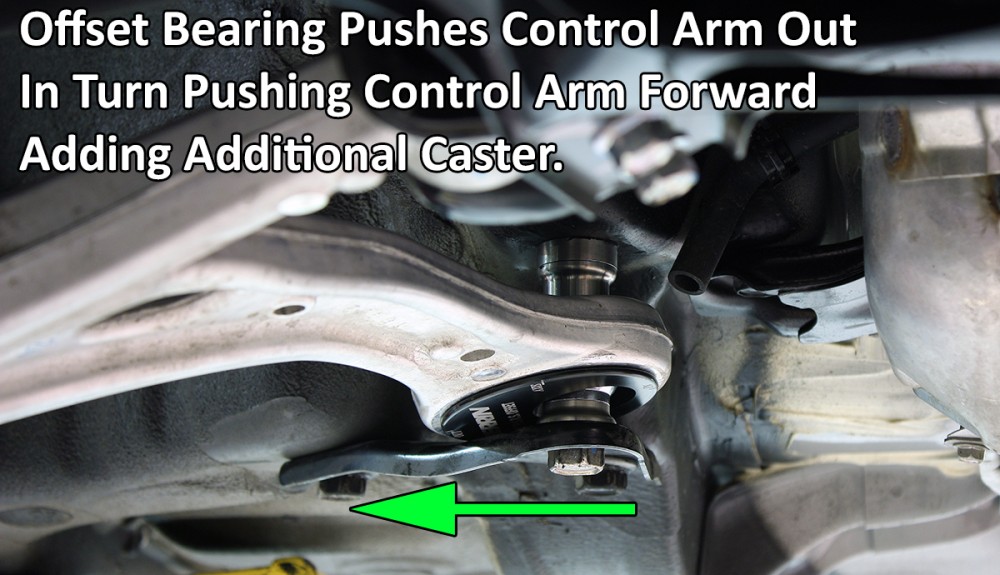

The next biggest features is in our offset version of the part. Most of the kits we make are offered with an optional offset bushing/bearing. This adds .5-1.5 degrees more caster to the cars front suspension. Caster is the angle that the front hubs turn at. If you stand next to your car and look at the front wheels, you might think that when you turn the steering wheel, the wheels rotated perpendicular to the ground, but in fact they don't. They always rotate on an axis that is offset toward the rear of the car (from the top of the hub). This angle helps do a lot of good things.

Why do you want castor? Castor helps reduce the amount of static camber needed on the front suspension. This helps with overall tire wear in a huge way. Imagine that castor increases negative camber to the outside wheel, and increases positive camber to the inside wheel making the angle of the contact patch of the tire better aligned to the road. Castor also helps the cars steering self center after a corner as well as track straighter down the road.

Most OEM suspension setups are done with a lot of compromises for alignment specs. Subaru has always been on the low side for castor specs, relative to other cars but that has changed over the years. For instance the 2002-2005 WRX has 3.0 degrees, 2004-2007 STI has 4.8 degrees, 2008-2014 has 6.25 degrees, and the 2015 STI has 8 degrees. You can see that Subaru has slowly changed it spec for castor over the years, and ending with what most people call the best handling Subaru to date.

Because of how we are adding castor, we are limited by the OEM control arm design and how much we can add. In most all kits we are able to add .5-.7 degrees of positive castor and on a few we are able to 1.1-1.2 degrees. There are other ways to change castor, but not using the same front lower control arm bushing we are replacing with the PSRS.

So why doesn't everyone get the offset bushing version of the PSRS? The only issue comes up when customers have really wide wheels and tires. Since we push the front wheels forward to get the extra castor, it pushes the wheels and tires closer to the fender liner. This mainly occurs on the 2008+ cars where 275 wide tires are a common upgrade. If that is an issue for y0u, then simply purchase the normal (zero offest) PSRS and you will have no tire rubbing or clearance issues at all.

Anti-Lift Geometry Changes

I hate the term ALK or Anti-Lift Kit. From the beginning we have battle with this because the other companies Anti-lift kit isn't keeping the car from lifting under acceleration or decelerating. Its really an Anti-Anti-Lift kit or pro-lift kit. The company that originally came up with the name describes the name as a fix for anti-dive/lift geometry, which has confused tons of customers, and also some of our team as well :)

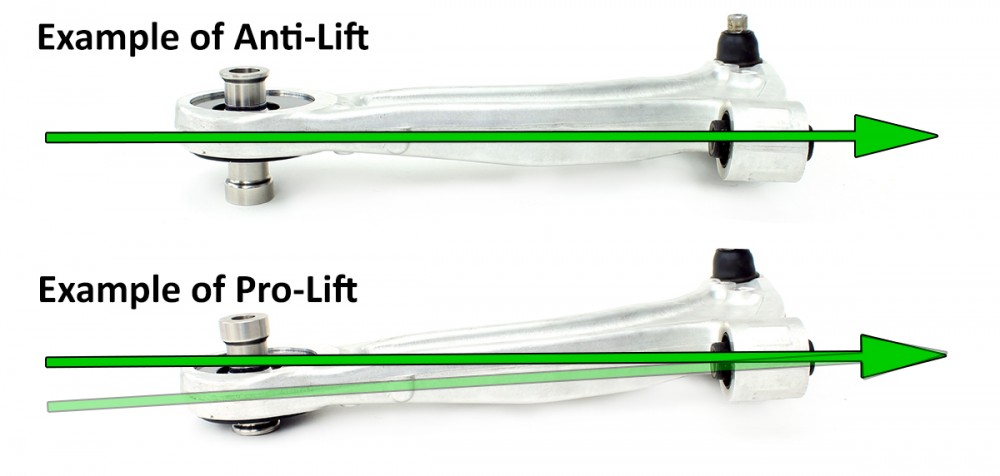

OEM's build "Anti-Lift" geometry into the front suspension help make the car appear more stable. What this does is reduce how much the front end will dive under braking, or raise under acceleration. To most normal customers, this is a good thing making the car appear to be more stable, but this does have some negative effects as it reduces weight transfer from front to back.

How does Anti-Lift geometry work? Imagine if your control arm is perfectly level to the ground at all times. When you hit the brakes, all that force is being pushed front to back on the arm and the only thing that compresses the suspension is the weight transferring and bumps. Now imagine the rear of the control arm being lower than the front. Under braking, that force is pushing the arm backwards and up, compressing the front suspension slightly along with the weight transfer and bumps. With the rear of the control arm lower than the front, the suspension compresses more, and more weight is to transfer to the front of the car.

Now look at it from the perspective of acceleration. With the rear bushing mounted lower than the front, as the wheels are pulling the car forward, it extends the front suspension down raising the front of the car. This transfers the weight to the rear of the car. Weight transfer is a good thing (to a point) to help put more weight on the tires that need the most traction. For instance under braking, additional weight helps front tires have more traction, and under acceleration, more weight transferring to the rear adds more traction to the rear tires.

Changing the geometry away from "Anti-Lift" toward "Pro-Lift" has many benefits, but this is not something customers will pick up on and notice. This is why we feel that this is a minor feature compared to the other things mentioned previously. ....

What Makes the PERRIN PSRS Different?

All of our PSRS kits over the years have been designed to be as deflection free as possible. Our first version of our 02-07 WRX PSRS used a spherical bearing, later moved to a hard plastic Delrin bushing, which significantly reduced our cost while still being deflection free. From that point on we always tried to incorporate the more expensive spherical bearings where we could. All newer Subaru's use control arms that have a vertically mounted round type bushings, which allows us to use the more expensive spherical bearing and keep the costs down.

Even more recently switched to a super hard polyurethane for our super popular 02-07 WRX PSRS. This allowed further reduction in cost and virtually no change to performance. While polyurethane is cheaper it does have its place, even with expensive cars like GT-R's.

There are a few applications where a spherical bearing could be used, but it adds huge amounts of complexity to the part or sacrifices some amount of durability. For instance on the Nissan GT-R, we used a hard polyurethane instead of the bearing because we needed to be able to adapt our part to the OEM control arm. Same goes for the MINI Coopers as they have a strange hex shape that we adapt to, and it was easier to make this out of polyurethane.

Besides our use of spherical bearings in many applications, we also exclusively use aluminum for each PSRS body. We see the use of steel sleeves that house urethane or other forms of steel used for the body. This sounds great but any customer of ours that lives in the eastern states where roads are salted and corrosion is very high, these never last. And even worse, are almost impossible to remove after a few years. Making the housings from aluminum not only allows for removal at some point, but also they are significantly lighter than steel versions. Some even use urethane in place of a body,which adds to amount of potential deflection. The less urethane you can use, the less deflection will occur. In the above GT-R and WRX PSRS, you can see how the thickness of urethane is pretty small, making the bushing stiffer overall.

We also try to make them as adjustable as possible. This ranges from offering another part number that has an offset bearing, or being able to press the body into a control arm at a different angle, or something like the GT-R PSRS that has a housing that can be bolted in a few different directions. When we first launched our PSRS's we only offered the offset style. After we had a lot of feedback from customers wanting a part they could install and NOT be forced to get an alignment done, we offered the zero offset versions. From that day on, we have offered both styles or offered one part number that would cover both.

Will I Really Notice The PSRS After Installation?

In most cases you will find a huge difference in how the car feels. But, that depends on the state of the car, which model of PSRS, and what car you are installing it on. For instance an 02 WRX with 130K miles will have a much softer bushing compared to a 2007 STI with 30K miles (uses the part). So an 2002 WRX customer is going to notice this way more than the 2007 STI customer purely based on wear and tear. Another example is an 2008 STI customer versus a 2014 STI customer. Between these two years (eliminating wear and tear) the 2014 STI has the newer larger rubber/spherical bearing type, and the difference in stiffness isn't as large. This is why on a 2014 STI we recommend the Offset PSRS, which will absolutely make a difference. As you can see the effects of installing our PSRS will vary depending on the car it is being installed , but in most cases the difference is very noticeable and will quickly become one of those things you wish the manufacture did from the beginning.